Analog to Ethernet Converter

Price 7500.0 INR/ Unit

Analog to Ethernet Converter Specification

- Connection

- RS-232/485 Serial (MODBUS)

- Weight

- 500 Grams (g)

- Application

- Centralised monitoring of plant parameters. Isolator

- Function

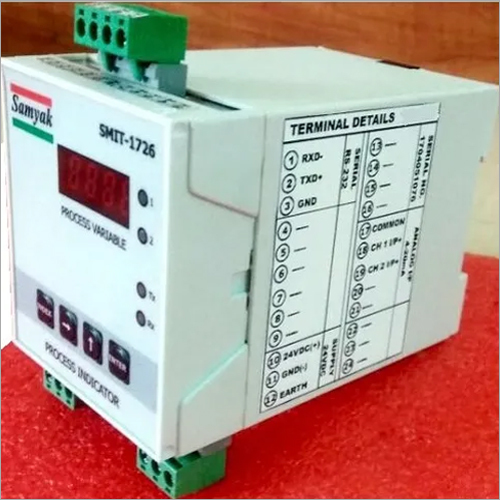

- This UNIT is based on a popular Microcontroller. It accepts up to 4 channels of Analog inputs. The converted data is displayed in engineering value and retransmitted as analog output for individual channel and also gives data on serial port RS-485/RS232.

- Size

- 70 mm(W) x 75 mm(H) x 110 mm(D)

Analog to Ethernet Converter Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 3 Week

- Main Export Market(s)

- Central America, Western Europe, Middle East, Africa, Asia, Australia, North America, South America, Eastern Europe

- Main Domestic Market

- All India

About Analog to Ethernet Converter

Input: Up to 4 channels (4 to 20 mA)

Interface:

- RS-232/485 Serial (MODBUS)

- TCP/IP Ethernet

Operating Voltage: 24VDC +/- 10%/110-230VAC (Factory configured)

Power rating < 20 VA

Key board: 4 keys keypad

Display: 4 digit, 7-segment RED led

Enclosure: General purpose, Plastic/polycarbonate, DIN rail/Wall mounting

Dimensions:

- 70 mm(W) x 75 mm(H) x 110 mm(D)

Optional:

- Analog Outputs: Up to 2 Channels: 4 to 20 mA, individually isolated

Application:

- Centralized monitoring of plant parameters

- Isolator

Versatility and Precision

Supporting both RS-232 and RS-485 serial connections with integrated MODBUS compatibility, this converter directly addresses the need for accurate real-time data acquisition. Each of its four analog channels translates readings into engineering values, making complex monitoring tasks seamless and precise across a range of plant environments.

Simplified Integration and Operation

The units compact dimensions and straightforward interface enable effortless installation within existing control systems. Its robust microcontroller ensures reliable performance, while data can be easily accessed either as analog outputs or via the serial port. Its durable build supports continuous data collection and transmission, crucial for plant monitoring in industrial settings.

FAQs of Analog to Ethernet Converter:

Q: How does the Analog to Ethernet Converter support plant parameter monitoring?

A: The converter collects up to four analog input signals from various sensors, translates these into accurate engineering values, and distributes the information as analog outputs and digital data via RS-232/485 serial communication. This enables centralized monitoring and better decision-making within industrial environments.Q: What are the main benefits of using this converter in an industrial setup?

A: This device simplifies data gathering and transmission, improves isolation between systems, and provides reliable real-time measurement output. It is particularly useful for manufacturers and exporters requiring accurate, centralized parameter monitoring and easy integration into MODBUS-compatible networks.Q: When should I use RS-232 versus RS-485 connections with this unit?

A: RS-232 is suitable for shorter distance, point-to-point applications, while RS-485 is ideal for longer distances and multi-device networks. Select the connection method based on your plants wiring layout and communication requirements.Q: Where can the Analog to Ethernet Converter be installed?

A: Thanks to its compact design (70 mm x 75 mm x 110 mm), the unit can be conveniently placed within control panels, monitoring stations, or equipment racks, making it ideal for use in centralized monitoring locations across various manufacturing or processing plants.Q: What is the process for retransmitting the converted analog data?

A: Once the analog signals are received and processed, the converter outputs the data as both engineering values and as new analog signals for each channel. Additionally, it transmits this data digitally through the RS-232 or RS-485 serial ports, allowing integration with MODBUS or similar protocols.Q: How does this converter enhance data reliability and security in industrial applications?

A: Serving as an electronic isolator, the unit minimizes signal interference and electrical noise between different plant systems, ensuring accurate and secure data transfer. Its sturdy construction further supports continuous and dependable operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Protocol Converter Category

Analog To Serial Converter

Price 10500.0 INR / Unit

Minimum Order Quantity : 1 Unit

Function : Converts analog signals (4 20 mA / 0 10 V) into serial data (RS232/RS485 MODBUS) for communication with PLC or SCADA systems.

Dimension (L*W*H) : 70 mm(W) x 75 mm(H) x 110 mm(D) Millimeter (mm)

Application : Centralised monitoring of plant parameters, Isolator

Weight : 500 Grams (g)

Serial To Analog Converter

Price 9500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Function : Serial to Analog Conversion

Dimension (L*W*H) : 70 mm(W) x 75 mm(H) x 110 mm(D) Millimeter (mm)

Application : Remote Monitoring System

Protocol Converter

Price 12500.0 INR / Unit

Minimum Order Quantity : 1 Piece

Function : This advanced unit is designed around a robust microcontroller, offering seamless acquisition and conversion of up to 8 channels of analog input.

Application : Centralized Process Monitoring, Data Logging & Acquisition, Industrial Isolator, Remote Sensor Management, Building Automation

Weight : 500 Grams (g)

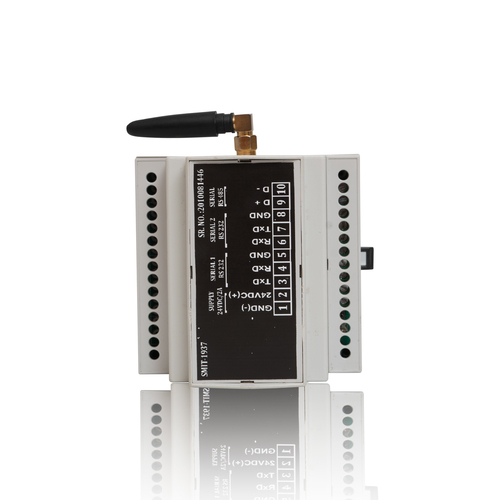

GSM Gateway SMIT 1937i

Price 12500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Function : Collects Data from Field Devices and transfer those data to cloud/server

Dimension (L*W*H) : 88mm (W) x 62mm (H) x 90mm (Depth) Millimeter (mm)

Application : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS