Bag Filling Controller WI 2009

Price 10500.0 INR/ Unit

Bag Filling Controller WI 2009 Specification

- Features

- Tare Facility, Auto Calibration, Batch Counting, High Speed, Easy Operation

- Display

- 6-Digit Bright Red LED Display

- Phase

- Single Phase

- IP Rating

- IP20

- Connectivity Type

- Potential-free Digital Output

- Mounting Type

- Panel Mounting

- Installation Type

- Panel Mounted

- Output

- Relay (NO/NC), 220 V AC, 5A

- Sensor Type

- Load Cell

- Current

- Approx. 0.5A

- Switch Type

- Tact Switch

- Measuring Range

- Up to 99,999 kg

- Protection Level

- Short Circuit & Overload Protection

- Usage & Applications

- Automatic Bag Filling Machines, Process Weighing

- Frequency

- 50 Hz

- Product Type

- Bag Filling Controller

- Operating Temperature

- 0C to 50C

- Working Temperature

- 0C to 50C

- Input

- Load Cell, Start & Stop Switch

- Application

- Industrial Bag Filling & Weighing Automation

- Supply Voltage

- 230 V AC 10%, 50 Hz

- Accuracy

- 0.01% of FS

- Dimension (L*W*H)

- 165 x 150 x 70 mm

- Weight

- Approx. 1.2 kg

- Humidity Range

- 95% RH (Non-condensing)

- Construction

- ABS Plastic Body

- Data Storage

- Non-volatile Memory for Count & Set Values

- Reset Facility

- Yes, Manual/Auto

- Alarm

- Overweight/Underweight Indication

- Power Consumption

- < 10 W

- Response Time

- < 100 ms

- Language Support

- English Display and Parameter Labels

- Control Logic

- Programmable Dual Set Point Logic for Coarse and Fine Feed

Bag Filling Controller WI 2009 Trade Information

- Minimum Order Quantity

- 1 Unit

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Middle East, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

About Bag Filling Controller WI 2009

Small volume, unique design, easy operation

Accepts input from 4-wire load cells

Digital Inputs: up to 4

Digital calibration with or without weights

Outputs:

- Control Output: up to 6 relays / Transistor

- Batch Over /Ready signal

- High precision 12/16-bit analog output

- RS232/RS485 Interface for Printing or Computer software

Fast, Moderate and Slow feeding

Digital filtering by adjusting:

- Step width, Moving Average

Password for calibration, operation parameters

Automatic zeroing when power up

Zero tracking

Configurable timings for all operations

Specifications:

Operating voltage: 24 VDC or 115-230 VAC

Display: 7-Segment LED or Alphanumeric LCD

Enclosure: Panel mount, General Purpose

The controller can be used in Master and Slave arrangement to improve speed Drum filling or Bagging.

Controller can be programmed to select predefined recipe by Digital inputs. One can wire selector switch on digital inputs.

Precision Meets Efficiency

The WI 2009 controller brings unmatched accuracy to bag filling operations, with 0.01% FS accuracy and dual set-point logic for coarse and fine feeding. Its fast response and reliable sensor integration streamline your production line, guaranteeing consistent results batch after batch.

User-Friendly Automation

Designed for effortless operation, the controller offers simple setup, auto calibration, and a bright, English-language display. The manual and auto reset options, along with batch counting features, make it ideal for diverse industrial applications requiring dependable and intuitive control.

Built for Industrial Demands

Constructed with a durable ABS plastic body and engineered for challenging environments, the WI 2009 operates efficiently within a wide temperature and humidity range. It provides IP20 protection, overload safeguards, and seamless panel mounting, ensuring longevity and consistent performance.

FAQs of Bag Filling Controller WI 2009:

Q: How does the dual set-point logic in the WI 2009 enhance bag filling accuracy?

A: The programmable dual set-point logic allows the controller to manage both coarse and fine feed stages automatically. This means it starts with a fast, bulk filling and transitions to a slower, precise fill near the target, reducing overfill and ensuring each bag meets specific weight requirements.Q: What types of alarms and notifications does the WI 2009 provide?

A: The controller is equipped with alarms for overweight and underweight conditions, alerting users immediately through its display and relays. This ensures any inconsistencies in bag weight are recognized and addressed before product moves further down the line.Q: When should the reset facility be used during operations?

A: The reset facility, available in both manual and automatic modes, should be used after each filling cycle or batch to clear previous data and prepare the system for the next operation. This helps maintain data accuracy and reliable batch counting.Q: Where is the WI 2009 bag filling controller best suited for installation?

A: This controller is specifically designed for panel mounting, making it ideal for integration into automatic bag filling machines and process weighing setups in industrial environments, particularly in manufacturing and packaging plants.Q: What is the process of data storage and retrieval in the WI 2009?

A: The device uses non-volatile memory to securely store count values and set parameters, ensuring that important operational data remains intact even during power interruptions. Data can be easily viewed on the LED display and managed via the panel interface.Q: How does using the WI 2009 benefit industrial bag filling operations?

A: By offering high precision, fast response, alarm notifications, and robust construction, the WI 2009 minimizes waste, reduces downtime, and streamlines batch tracking. Its user-friendly features enhance productivity and reliability for manufacturers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Batch Controller Category

Batch Controller SMIT 1523

Price 55000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 year

Dimension (L*W*H) : 244 (W) x 160 (H) x 100 (D) Millimeter (mm)

Product Type : Serial RS232/RS485 for Printer/Computer. USB port for PEN Drive (Mass data storage). GSM Modem to connect with Cloud/Server.

Water Dispenser SMIT-1272

Price 5000.0 INR / Unit

Minimum Order Quantity : 1 Piece

Warranty : 1 year

Dimension (L*W*H) : 66 mm x 66 mm Millimeter (mm)

Product Type : Digital Indicator

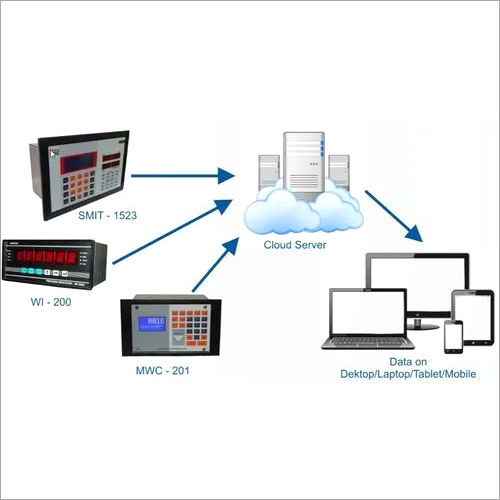

Batch Controller Unit For Mobile Application

Price 60000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 year

Dimension (L*W*H) : 244 (W) x 160 (H) x 100 (D) Millimeter (mm)

Product Type : Microcontroller based

Remote Monitoring System

Price 13500.0 INR / Unit

Minimum Order Quantity : 1 Piece

Warranty : 1 year

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS